Industry News

Smart Warehousing VS Traditional Warehousing

1. Definition and Classification of Smart Warehousing

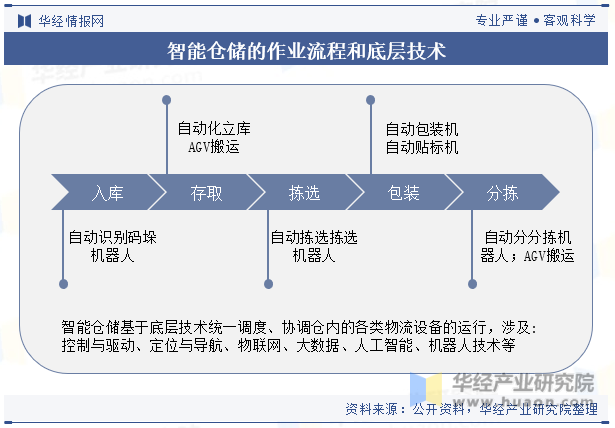

Smart warehousing is an integral part of the logistics process, encompassing steps such as inventory entry, storage and retrieval, picking, packaging, sorting, among others. It leverages underlying technologies including control and drive systems, positioning and navigation, the Internet of Things (IoT), big data, artificial intelligence (AI), and robotics to uniformly dispatch and coordinate the operation of various logistics equipment within the warehouse. Its primary advantages over traditional warehousing include: high space utilization, three-dimensional storage, saving over 70% of land; dynamic storage, integrating and coordinating upstream and downstream operations; unmanned machine manipulation, reducing labor costs, and improving accuracy.

2. Comparison Between Smart Warehousing and Traditional Warehousing

Smart warehousing boasts numerous advantages such as enhanced land utilization efficiency, reduced labor costs, minimized material waste, lower material picking error rates, and improved automation and management levels in warehousing. Storing materials on high-level shelves optimizes space utilization, significantly reducing ground area usage and land use costs. Compared to traditional warehouses, smart warehousing reduces land usage by over 40%, achieving favorable economic benefits. Additionally, the introduction of software like WMS enhances overall management accuracy, effectively addressing issues of inventory backlog.

A comparative analysis from seven aspects—space utilization, storage form, accuracy, management level, traceability, environmental requirements, and efficiency and cost—is presented below:

① Space Utilization:

Traditional warehouses occupy large areas with low space utilization.

Automated立體warehouses, on the other hand, fully utilize vertical space, offering significantly higher storage capacity per unit area compared to traditional single-story warehouses (approximately 4-7 times).

② Storage Form:

Traditional warehouses employ static storage, serving solely as storage locations for goods, lacking efficient goods management.

Automated立體warehouses adopt dynamic storage, enabling automatic goods retrieval and storage on demand, with warehouse systems closely integrated with other production systems.

③ Accuracy:

Traditional warehouses have low informatization levels, prone to errors.

Automated立體warehouses employ advanced information technologies, ensuring high accuracy.

④ Management Level:

Traditional warehouses have limited computer application, with warehousing disconnected from other production processes, leading to inventory backlog.

Automated立體warehouses utilize computer-based intelligent management, tightly integrating warehousing with other production processes, effectively reducing inventory backlog.

⑤ Traceability:

Traditional warehouses rely heavily on manual registration, compromising data accuracy and timeliness.

Automated立體warehouses utilize barcode technology and information processing techniques for accurate tracking of goods flow.

⑥ Environmental Requirements:

Traditional warehouses are highly susceptible to special environments like darkness, low temperatures, and toxicity.

Automated立體warehouses can adapt to such special environments.

⑦ Efficiency and Cost:

Traditional warehouses rely heavily on manpower, resulting in slow goods retrieval and high labor costs.

Automated立體warehouses are highly mechanized and automated, offering fast inventory turnover and low labor costs.