Company News

HERO Intelligence: automated equipment and real-time planning to create an efficient production and logistics system

Adopting automation equipment to improve production and flow efficiency

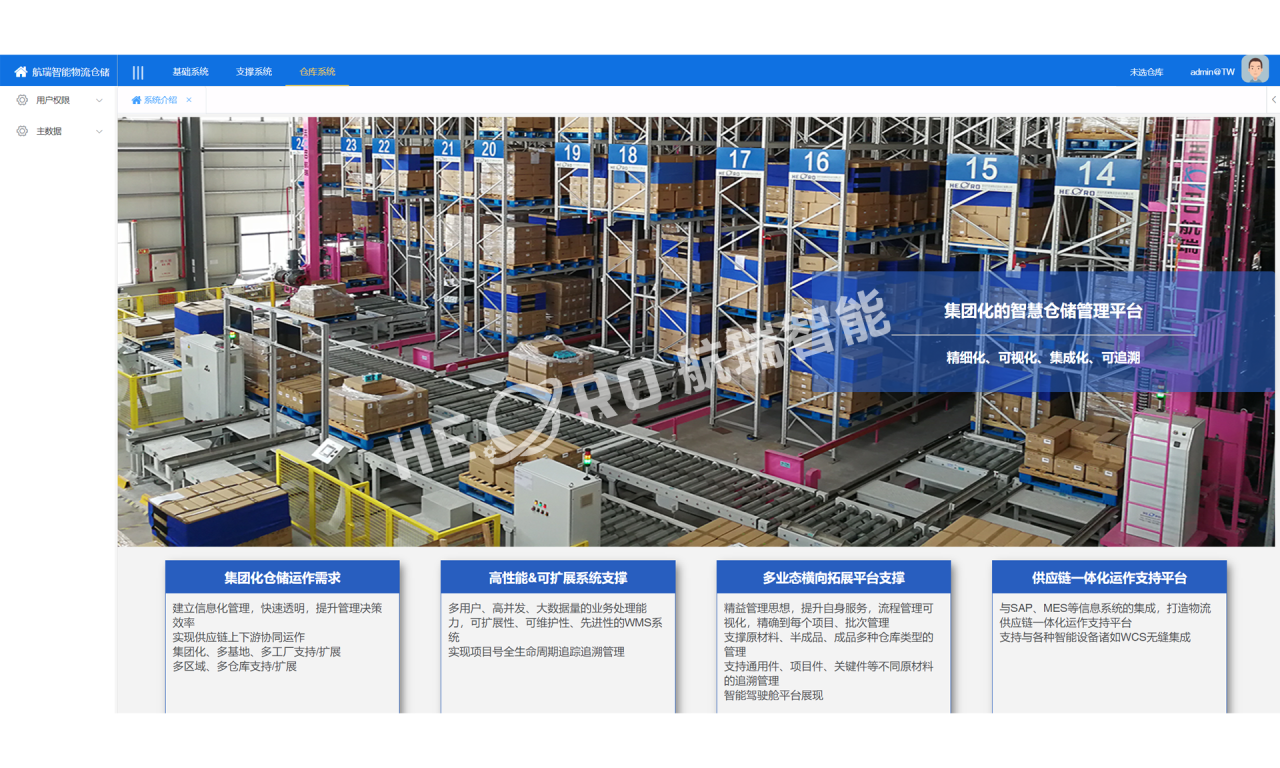

In warehousing, HERO Intelligence adopts automated three-dimensional warehouse and AGV and other material handling equipment, which effectively reduces manual handling, accelerates the speed of material access, and at the same time, reduces the error rate caused by manual operation, and guarantees the rapid and accurate operation of warehousing operations.In the production line, the use of robots and automated intelligent equipment to perform repetitive tasks, significantly reducing human intervention, not only improves the production speed, but also greatly improves the stability of product quality, providing a solid guarantee for the stable production of enterprises.

Real-time dynamic route planning, optimize the logistics flow path

With the close cooperation of WMS, WCS and other informatization software, HERO Intelligence detects the data status of production and logistics equipment in real time, dynamically plans the logistics routes and scheduling, flexibly responds to the sudden changes in routes, reduces the reduction of the flow efficiency due to the irrational route planning, and ensures the smoothness and efficiency of the logistics flow.

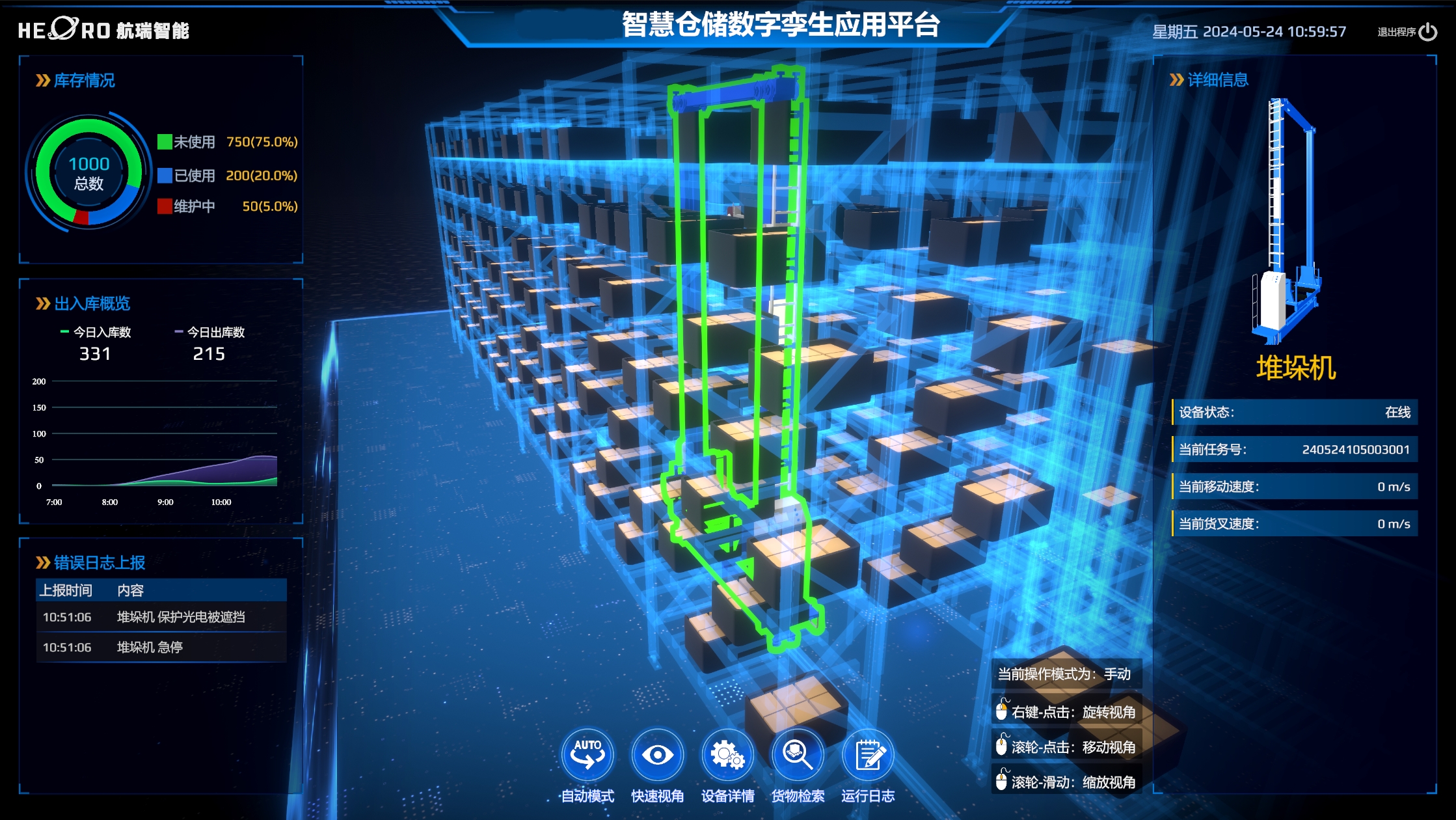

HERO Intelligence makes full use of the Internet of Things (IoT) technology to extensively collect equipment and operational data. With the visualization characteristics of digital twin software, real-time monitoring of production and logistics processes. Through the in-depth analysis of massive data, the efficiency bottlenecks in the production and logistics process can be quickly identified. Based on the results of these analyses, to optimize the process for the enterprise to provide targeted and effective solution basis to help enterprises continue to improve the overall operational efficiency.

Carry out predictive maintenance to ensure the efficient operation of equipment

Through in-depth analysis of the collected equipment data, HERO Intelligence uses software such as digital twins to visualize and analyze equipment failures. The system can inform the potential failure of the equipment in advance, and send out warning signals in time, and arrange the maintenance personnel to carry out targeted maintenance once again. This predictive maintenance mode effectively avoids production interruptions due to sudden equipment failure during the production process, ensures that the equipment is always in an efficient operating state, and provides strong support for the continuous production of the enterprise.