Company News

Hero Intelligent empowers food cold chain enterprises to build -18℃ frozen food intelligent cold storage, to realize the intelligent upgrade of warehousing!

Jinjian frozen food, deep plowing rice, noodles, frozen seasoned food field, is the Hunan Grain Group and Jinjian rice industry strong combination of Ningxiang Economic Development Zone in the Food Industry Park to build key projects, but also the park's first production project. In order to meet the high quality of frozen food storage and stable and efficient low-temperature logistics delivery needs, while reducing the burden of staff working in low-temperature environments, Jinjian frozen food hand in hand with Hero Intelligent, jointly created a library capacity of up to 5500 tons, low temperature of -18 ℃ of the intelligent cold storage.

Aiming at the special characteristics of food cold storage, Hero Intelligent comprehensively analyzed the challenges faced by the products in low-temperature operation and broke them down one by one, and tailored the intensive storage solution of “stacker system + shuttle system + high-level shelves + in and out of the warehouse system + control and management system” for Jinjian Frozen Foods. This solution realizes the automated operation of frozen food from entering, storing and exiting the warehouse, effectively replaces the repetitive labor under low temperature environment, and greatly improves the efficiency of warehousing operation.

1. High-level three-dimensional shelves up to 13.5 meters, shuttle plate bull-leg shelves and double-bay beam shelves with inventory capacity of up to 5,500 tons, to fully meet the large-scale storage needs of frozen food.

2. Frozen food is packed, palletized and automatically put into storage by robots, which improves the operational efficiency and accuracy of storage.

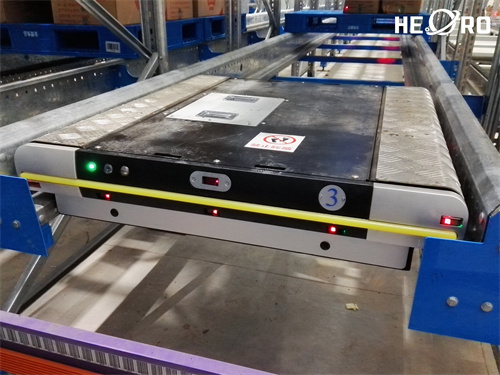

3. Intelligent equipments such as stacker cranes, intelligent shuttles and conveyors are specially designed to operate stably at a low temperature of -18°C. Under the unified scheduling of WMS, intelligent access and automated handling are realized, which greatly improves the turnover efficiency of frozen food and strictly follows the principle of “first-in-first-out” to easily cope with the challenges of large-scale storage and retrieval of frozen food. Strictly follow the principle of “first-in-first-out”, and easily cope with the challenges of large-scale storage.

4. Through the deployment of WMS, WCS and other intelligent systems, the project realizes the unification of logistics and information flow, improves information accuracy, optimizes the warehouse management process and ensures food safety.